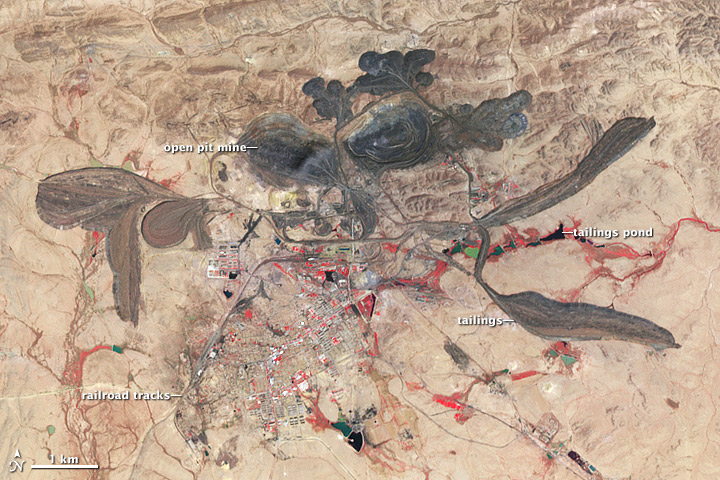

Enlarge / About half of the world's rare earth element supply comes from this single mine. (credit: NASA)

A variety of modern technologies, including permanent magnets that have been used in everything from earbuds to wind turbines, rely on rare earth elements. While the metals aren't actually especially rare, they don't occur at high concentrations in the Earth's crust. As such, extracting them is expensive and tends to produce a lot of environmental damage, meaning that most of the supply comes from a small number of countries (see the chart here), leaving the supply at risk of political fights.

So the potential to get much more out of existing rare earth mines is obviously very appealing. And the method described in a paper released on Monday seems to offer it all: more metal per ore, much lower cost, and far less worry about mining waste.

Less leaching

Many of the best rare earth deposits occur in places where nature has concentrated the elements for us. These tend to be sediments formed from materials where the rare earth elements will react or interact with the sediment, coming out of solution and gradually building up the concentration in the ore. The usual method of extracting the elements from these ores essentially involves reversing that process. An ion-rich solution is pumped through the ore, and these ions displace the rare earths, allowing them to leach out of the ore. Typically, the solution used is ammonium sulfate.

Read 13 remaining paragraphs | Comments